Lindapter Girder Clamps provided a solution for the installation of district heating pipes during the bridge refurbishment.

Location: Magdeburg, Germany

Market: Bridge

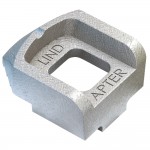

Product: Type A & B Girder Clamps

Contractor: Schottstädt und Partner Tiefbau GmbH

The Magdeburg Bridge was inaugurated in 1965 and spans 850 feet over the river Elbe in Magdeburg, Germany. It connects Magdeburg's old town with the Elbe island of Rotehorn and the Werder district located there. In addition to two lanes for tram traffic, the structure has four lanes for motor vehicles and footpaths and cycle paths on both sides.

The bridge was identified as requiring refurbishment due the amount of rust that had built up over the years. The proposed work included, removing the rust, applying a new corrosion protection coating and then installing piping to the underside of the bridge that was essential for the district heating system in the town. There were four pipes that had to be installed, two for the heating, one to carry water and the other gas, the client wanted a solution for connecting the pipes to the bridge that would not damage the new protective coating.

Additional steel beams were to be installed to the underside of the bridge and pipe hangers with wheels attached to them. The wheels on the pipe hangers were to allow for expansion of the pipes horizontally due to temperature changes. Lindapter Type A & B Girder Clamps in a four-bolt configuration with location plate and packing pieces were specified on the project to connect the secondary steel to the bridge because they would not damage the protective coating and also due to their load capacity and range of independent approvals.

The client was concerned that clamps could become loose overtime due to the vibrations caused by the trams on the bridge deck above, and the additional cost of maintenance if they had to go under the bridge to retighten them. To provide extra reassurance and for a “belt and braces“ approach anti-vibration washers were specified with the girder clamps.

To begin with a temporary “red” steel frame and moveable platform were installed to the underside of the bridge to allow the installation of the heating system pipes. The additional steel beams to support the pipes were then connected to the bridge using 2,952 Lindapter Type A & Type B girder clamps and 369 location plates. Installation was straightforward with each bolt inserted through the Type A clamps and pre-drilled holes of the location plate with the required packing pieces then added, followed by the Type B clamp, anti-vibration washer and finally the hexagon nut that was tightened with a torque wrench to the recommended torque.

Lindapter Type A & B Girder Clamps provided a solution for connecting the pipes to the bridge without damaging the new protective coating. The approved solution provided the reassurance to all parties involved with the project that the product was more than fit for purpose. The Lindapter products were all supplied in a hot dipped galvanized finish to provide the connections with a high level of corrosion protection, this will ensure a longer lifespan and reduce maintenance costs over the lifetime of the bridge.

- No damage to the protective coating

- Independently approved solution

- High corrosion protection hot dipped galvanised finish

- Combination of clamps with anti-vibration washers

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.