Lindapter’s Type ALP Adjustable Lifting Points provided a quick, non-intrusive solution for securing lighting supports, preserving the venue's heritage while meeting safety standards.

Location: London, UK

Market: Arts / Entertainment / Staging

Contractor: WFC Contractors

Installer: Outback Rigging

Product: Type ALP

Once known as the legendary Café de Paris, this lavish event space, which once hosted icons like Judy Garland, Frank Sinatra, and Grace Kelly, had fallen into disrepair by the time WFC began its refurbishment in July 2022. The transformation of Café de Paris into Lío London aimed to modernize the venue while maintaining its historic character. Renowned for its luxurious cabaret performances, the venue needed an upgraded lighting system that could enhance the visual experience of each performance. The challenge was to integrate modern lighting supports without compromising the building’s architectural integrity.

The installer, Outback Rigging, needed a readily available, off-the-shelf solution to meet the project's tight deadline. The installation process had to be quick to minimize downtime, while also ensuring a secure and reliable attachment method for the heavy and dynamic lighting fixtures. Adjustability was also a priority, allowing precise positioning of the lights to optimise stage effects and enhance the audience experience.

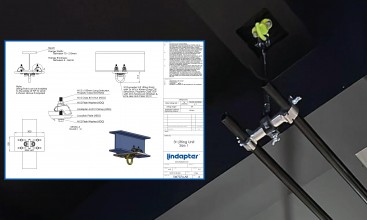

Lindapter’s Adjustable Lifting Points (ALP3T-1 and ALP3T-2) were selected for their high load capacity and adaptability. These lifting points provided a secure attachment method without requiring drilling or welding, preserving the venue’s existing steel structure while ensuring compliance with safety regulations. Their adjustable design allowed for precise alignment of the lighting supports, improving the overall stage setup. Additionally, as an off-the-shelf solution, the Type ALPs were readily available, helping to keep the project on schedule.

The Type ALP lifting points were installed onto the existing steel beams without any modifications, such as drilling or welding. Their adjustable design allowed for real-time positioning adjustments, ensuring that the lighting was precisely aligned to maximize the stage’s visual impact. The user-friendly design of the lifting points enabled the installation team to complete the process quickly and efficiently, maintaining both safety and reliability while staying within the project’s timeline.

The refurbishment of Lío London revitalized the venue’s iconic structure, successfully integrating modern engineering with the preservation of the venue’s historic charm. Lindapter’s Type ALP Adjustable Lifting Points provided a secure and reliable solution for attaching lighting supports, meeting strict safety standards. The non-intrusive installation preserved the building’s architectural integrity, avoiding permanent alterations such as drilling or welding. The installation was completed on time, allowing the venue to reopen as scheduled and welcoming audiences to enjoy its refreshed, yet timeless, ambience.

- Time-Saving Installation: Quick, efficient, off-the-shelf solution.

- Enhanced Safety: Secure, stable, meets safety standards.

- Preservation of Structure: Non-intrusive, no drilling required.

- Adjustability: Real-time, precise lighting alignment.

- Cost-Effectiveness: Reduced costs, no bespoke fabrications.

- Versatility: Handles high loads with ease.

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.