Reasons to choose Lindapter

-

Save time and money

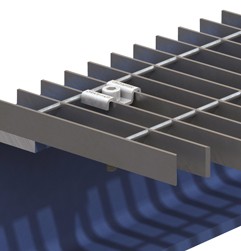

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

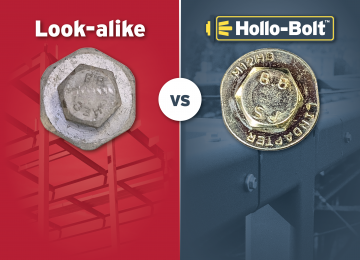

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

Our approved steel clamping systems offer a solution for

overcoming challenging steel connections.

We are the global leader of steel clamping systems and girder clamps that provide a faster, cost-effective alternative to drilling or welding. Whether you are designing a structural frame, connecting to existing steel or installing building services, our vast range of high quality products will provide a solution for the following applications…

Latest news

Read more articlesHow can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.