Lindapter Girder Clamps secured secondary steel to support heavy duty pipes.

Location: London, UK

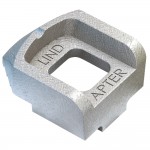

Product: Type A Girder Clamps

Market: Building Services

Client: NHS Foundation Trust

Installer: Fascel Group

Great Ormond Street Hospital opened in 1852, and has grown into one of the world’s leading children’s hospitals for paediatric care and research. However most of the hospitals buildings are nearing the end of their useful lives and are becoming increasingly inadequate. In 2004 an ambitious four-phase redevelopment programme to rebuild two thirds of the hospital site over a 20-year period began.

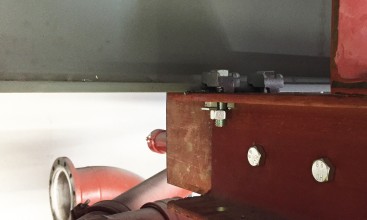

The latest redevelopment at the hospital site required a safe and secure method of connecting secondary steel to the main structural frame. This secondary steel would support heavy-duty mechanical pipework and building services pipes around the building. Engineers also required the supports to be adjustable to allow for onsite tolerances.

Lindapter worked with the engineer to design a simple but effective connection detail using Lindapter Type A Girder Clamps. Steel sections connected to the main structural beams using Type A girder clamps were specified. The steel section crossed the existing steel at 90 degrees and provided the necessary tensile strength to support further secondary steel below and the pipes.

Installation was quick and easy as each bolt was simply inserted into predrilled holes in the new steel sections with the Type A on one end and nut on the other. The adjustability of the girder clamps allowed the contractor to align the steel sections into the exact positions required. To complete the installation, the recessed top of the clamp held the bolt captive while the nut was tightened with standard hand tools, quickly achieving a safe and secure connection.

Lindapter girder clamps provided fast installation and avoided costly field drilling or welding. The adjustability of the girder clamps also gave the contractor flexibility to overcome any alignment issues in the field. Girder clamps have independent technical accreditations, including the CE mark (ETA-13/0300), TÜV and Lloyd’s Register approvals. These accreditations verify the tensile load capacities that led to a safe installation.

- No drilling or welding required

- Fully adjustable onsite for easy installation

- Hot Dipped Galvanized finish offers a cost effective and low maintenance solution

- CE Mark (ETA-13/0300), TÜV and Lloyd’s Register approvals

Want to find out more about this product?

Watch the

installation video

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

Drilling and welding in the field is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection detailing

Lindapter’s experienced Engineers can detail a custom connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.