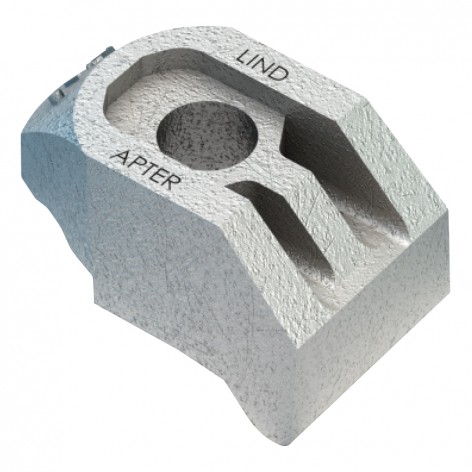

Type AF High Slip Resistance Girder Clamp

Heavy duty girder clamp used to quickly connect steel beams with flat or tapered flanges. High slip resistance for tensile, frictional and combined load applications.

Overview

The Type AF girder clamp is used to achieve a fast steelwork fixing connection where high load capacities are present in either tensile, frictional or combined load directions. It has a recessed top to hold the bolt head captive while the nut and washer are tightened down using only one tool, alternatively use a Type AFW washer to convert the recess to a flat top. The skirt on the underside of the clamp abuts the edge of the beam flange and prevents the clamp rotating during installation. Manufactured from SG iron with a hot dip galvanised finish to provide high performance and anti-corrosion protection.

NEW Independently fire tested in accordance with ISO 834 for a duration of 120 minutes. For further details and load data please contact Lindapter.

Features & Benefits

- NEW: Independently fire tested in accordance with ISO 834

- High slip resistance clamp evaluated for tensile, frictional and combined load applications.

- 70kN static slip resistance or 250kN tensile (AF24 with 4 x property class 10.9 fasteners).

- Recess holds the bolt head captive (property class 8.8).

- Suitable for parallel and tapered flanges up to and including 10°.

- The tail spans slotted clearance holes.

- Lindapter recommends the use of DTI Washers conforming to EN14399-9 with the Type AF.

- Independently approved for dynamic load applications to EN 1993-1-9. Contact us for more details.

Tail Lengths & Packing Pieces

The clamp is available in two tail lengths, Short or Medium, and can be used with Lindapter packing pieces to increase the clamping range. Choose the correct combination of tail length and packing pieces to suit a specific flange thickness. Download datasheet for selection table.

Location & End Plates

These plates ensure the clamps and bolts are located in the correct position relative to the supporting steelwork. Location plates are simple fabricated items designed to sit between the two sections to be clamped together to ensure the bolts are fixed at the correct centres. End plates are simple fabricated items that are pre-welded to support frames, bracket or sections, allowing connection to the supporting structure with standard Lindapter clamps. Download datasheet for further information.

Properties

- Manufactured from SG iron to BS EN 1563.

- Available with hot dip galvanised finish.

- Reaction to fire: A1 (Steel)

Durability and corrosion protection:

| Corrosivity Class | Galvanised Steel |

| C1 | More than 50 years |

| C2 | More than 50 years |

| C3 | More than 20 years |

For C4 and C5 corrosion categories contact us.

Technical Specification

| Bolt | Safe Working Loads | Dimensions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Code | Size Z | Property Class4) | Tensile / 1 Bolt (FOS 5:1) | Slip1) / 2 Bolts (FOS 2:1) | Tightening Torque* | Tail Length | Y | X | T | T | Width | ||

| Painted Steelwork2) | Galvanised Steelwork | short v1 | medium v2 | Type AF | Type AF with AFW | ||||||||

| kN | kN | kN | Nm | mm | mm | mm | mm | mm | mm | mm | |||

| AF12 | M12 | 8.8 | 8.5 | 3.4 | 3.9 | 90 | 5 | 12.5 | 27 | 27 | 17 | 22 | 39 |

| AF16 | M16 | 8.8 | 16.0 | 8.0 | 10.0 | 240 | 8 | 15 | 35 | 37 | 22 | 27 | 49 |

| AF20 | M20 | 8.8 | 26.3 | 13.0 | 16.0 | 470 | 10 | 18 | 40 | 39 | 25 | 31 | 56 |

| AF24 | M24 | 8.8 | 40.0 | 24.0 | 30.0 | 800 | 15 | 30 | 48 | 60 | 32 | 42 | 82 |

| AF12 | M12 | 10.9 | 10.0 | 4.0 | 5.2 | 130 | 5 | 12.5 | 27 | 27 | 17 | 22 | 39 |

| AF16 | M16 | 10.9 | 19.5 | 11.0 | 12.0 | 300 | 8 | 15 | 35 | 37 | 22 | 27 | 49 |

| AF20 | M20 | 10.9 | 30.0 | 20.0 | 25.0 | 647 | 10 | 18 | 40 | 39 | 25 | 31 | 56 |

| AF24 | M24 | 10.9 | 62.53) | 28.0 | 35.0 | 1000 | 15 | 30 | 48 | 60 | 32 | 42 | 82 |

1) Slip resistant values calculated against movement exceeding 0.1mm.

2) Shot blast and painted steelwork.

3) 3.2:1 Factor of Safety.

4) For ease of installation when using 10.9 bolts Lindapter recommends using fastener assemblies to EN 14399-1.

* Torque figures based on bolts / setscrews in an unlubricated condition.

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoC No.104

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoC No.104

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.004

For Characteristic Resistances when designing a connection to Eurocode 3, please refer to DoP No.004

• Independently tested for dynamic load applications to EN 1993-1-9.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.