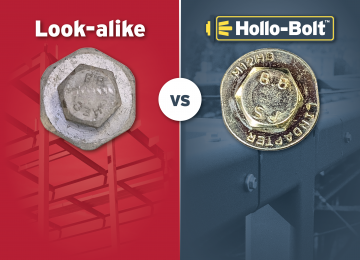

In the construction industry, small details make the biggest difference. A connection may look simple, a bolt into a hollow steel section, but when it comes to structural integrity, appearance can be dangerously misleading.

Today, there are a few products on the market that resemble the Hollo-Bolt®. They may look the same, but they will not perform the same. Unauthorised copies often fail to deliver the same high strength, fatigue resistance, or safety factors. The result? Increased risk of structural failure, higher lifetime costs, and exposure to liability.

That’s why it’s crucial for engineers, contractors, and asset owners to understand the difference between the original Hollo-Bolt, invented by Lindapter in 1995 — and look-alike products that cannot guarantee the same performance or approvals.

The First Expansion Bolt for Structural Steel

The Hollo-Bolt® was a revolutionary industry-first. Introduced in 1995 by Lindapter, it enabled engineers to create fast, safe, and approved connections to Structural Hollow Sections (SHS) without the need for welding or on-site drilling.

The concept is elegantly simple:

- The bolt is inserted into a pre-drilled hole in the steel section.

- As it is tightened, an internal cone is drawn up, expanding the sleeve against the inner wall of the steel.

- The result is a secure, high-strength connection that is approved for structural applications.

This innovation opened new possibilities for architects and engineers designing with hollow sections, making structures faster to build, safer to erect, and more cost-efficient to maintain.

Genuine Lindapter Hollo-Bolts — Engineered for Safety, Proven by Certification

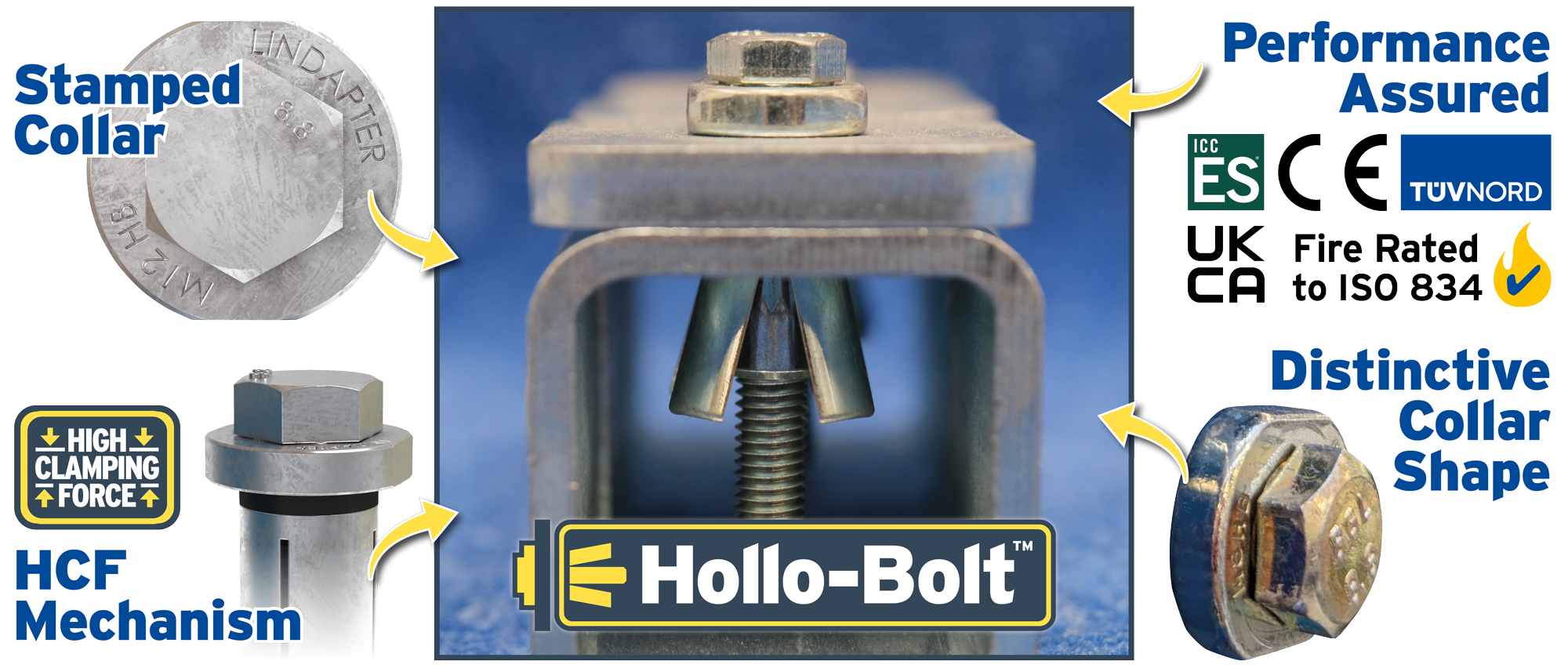

When it comes to structural connections, there’s simply no substitute for genuine Lindapter Hollo-Bolts. Every detail, from the stamped identification to the patented High Clamping Force (HCF) mechanism is designed, tested, and verified to deliver lasting performance and total peace of mind.

1. Easy Identification

Each genuine Hollo-Bolt is clearly stamped with the word “Lindapter”, followed by the size (for example, M8HB). This permanent marking appears on the collar, providing instant assurance that the product you’re installing is authentic and traceable.

2. Backed by Multiple Independent Approvals

Only Lindapter Hollo-Bolts are supported by comprehensive, third-party certifications including ETA, CE Marking, and ICC-ES approvals that confirm their suitability for structural applications worldwide. These approvals are your evidence of compliance, verifying that every Hollo-Bolt has undergone rigorous testing for load capacity, safety, and performance in real-world conditions.

3. Distinctive Collar Design

Look closely at the collar: genuine Hollo-Bolts feature two flat, parallel sides, a signature design detail that helps installers quickly align and recognise the product on-site. This design not only improves usability but also acts as an immediate visual cue of authenticity.

4. High Clamping Force (HCF) Innovation

The HCF Hollo-Bolt, available exclusively in M16 and M20 sizes, represents Lindapter’s ongoing commitment to innovation. It delivers three times more clamping force than standard designs, significantly reducing displacement and enhancing resistance to vibration and dynamic loads. It’s the go-to choice for engineers who demand maximum strength and long-term reliability.

Why Risk It?

Using imitation or “look-alike” bolts may seem like a cost-saving shortcut but it can have serious consequences. Unapproved alternatives lack the independent testing, traceability, and documented performance data that engineers depend on to demonstrate compliance with building safety regulations. In structural applications, the smallest deviation in design or material quality can lead to reduced load capacity, unexpected movement, or even failure under dynamic conditions.

With Lindapter, you’re not just buying a bolt, you’re investing in verified safety, traceability, and proven engineering integrity. Genuine Hollo-Bolts protect both your structure and your reputation.

Advantages Over Traditional Methods

No Hot Works

By eliminating welding on site, Hollo-Bolts remove the need for hot works permits, fire watch, and costly safety procedures. This translates into safer working environments and reduced insurance premiums.

Time Savings

Installed with standard hand tools, Hollo-Bolts drastically reduce installation time compared to drilling through both sides of a hollow section or welding in difficult-to-access areas.

Cost Efficiency

Faster installation means fewer labour hours, less disruption to operations, and fewer hidden costs, particularly important for rail, offshore, and industrial facilities where shutdown time is measured in millions.

Performance vs Alternatives

Compared to through-bolting, which requires access to both sides of a section and can compromise aesthetics, Hollo-Bolts delivers a clean, flush finish. Unlike cheap copies, the original Hollo-Bolt is tested, certified, and proven in some of the world’s most demanding environments.

Design Flexibility: Head Types and Finishes

The Hollo-Bolt range offers multiple head types to suit aesthetic and functional requirements:

- Hexagonal Head – The standard choice for heavy-duty structural applications.

- Countersunk Head – Ideal where clearance or architectural detailing is required.

- Flush Fit Head – For concealed connections, often specified in high-end architectural steelwork.

Engineers can also choose from a wide selection of coatings and finishes, such as zinc plating, hot-dip galvanising, sheraplex or stainless steel, to ensure long-term durability in any environment, from indoor commercial builds to aggressive offshore conditions.

Installation and Removal

Installing a Hollo-Bolt is straightforward:

- Drill a single hole through one side of the hollow section.

- Insert the Hollo-Bolt and tighten with a standard wrench or impact driver.

- The internal mechanism expands, locking the fixing securely in place.

Removal is just as simple, reverse the tightening process, leaving no permanent damage to the steelwork. This allows for future modifications, adjustments, or dismantling without compromising the structure.

Case Studies

The Hollo-Bolt has been trusted in thousands of projects worldwide, across industries where performance and safety cannot be compromised:

- Military History Museum (Germany): Lindapter Hollo-Bolts provided a solution for securing an extensive perforated steel cladding façade.

- Wilshire Grand Center (California, USA): Lindapter Hollo-Bolts provided a solution for securing a huge architectural curved skylight atrium.

- Upgrade ITER Nuclear Fusion Megaproject (France): Lindapter Hollo-Bolts provided a solution for securing Structural Hollow Section beams and pipe supports.

Each case demonstrates not only the versatility of the Hollo-Bolt, but also its unique ability to deliver certified strength, ease of installation, and lifetime savings.

Choose the Original, Choose Safety

The Hollo-Bolt remains the gold standard for hollow section connections. It is the only product in its category with a proven 30-year track record, comprehensive approvals, and an international reputation for safety and reliability.

Look-alikes may copy the design, but they cannot copy the approvals, the testing, or the confidence that comes with Lindapter engineering.

When the performance of your structure and the safety of people is on the line, don’t take chances. Specify the original Hollo-Bolt.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.