Lindapter announce the launch of their new brochure “Solutions for Dynamic Load Applications”.

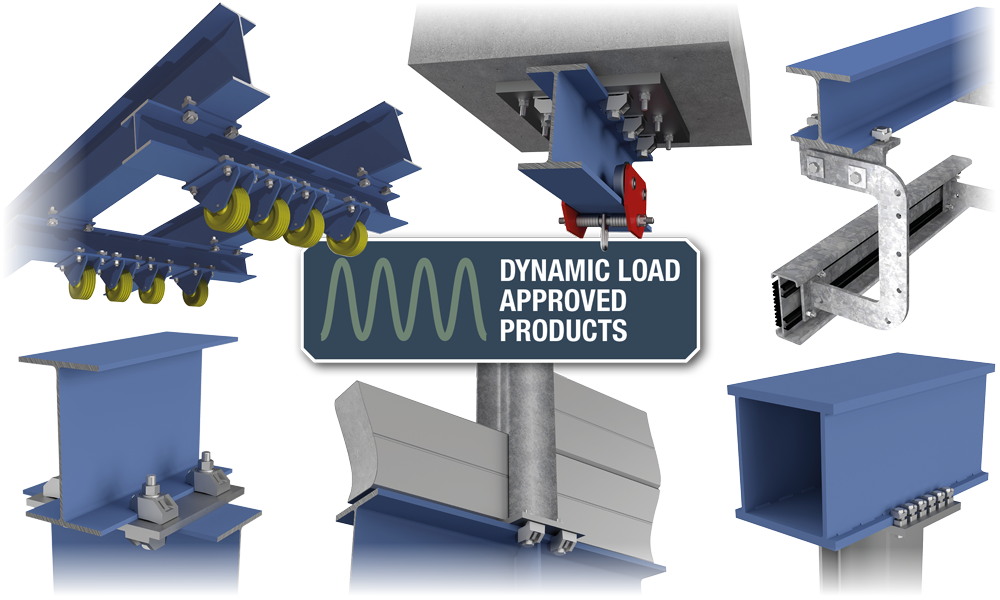

Lindapter provides a unique range of approved steelwork solutions for overcoming challenging steel-to-steel connections. Our products are used extensively around the world and are the ideal solution for applications that have Dynamic Loads.

This brochure provides examples of steel-to-steel connections using Lindapter products in many different applications. The products shown have been independently tested and approved for use in Dynamic Load applications so you can be confident of specifying them on your next project.

Lindapter has gained ETA / CE Mark approval of its Type AF and Type AAF Girder Clamps for use in dynamic loading applications. This development extends the range of approved options available to Engineers when designing dynamic connections to Eurocode 3, which also includes Types A and B Girder Clamps. Dynamic loading capacities for these products have been published in Lindapter’s Declaration of Performance documents.

These latest third party approvals are in addition to independent dynamic load testing commissioned by Lindapter for its Hollo-Bolt, Type AF and Type AAF products in order to offer specifiers an economic and technically improved connection compared to welding or through bolting for dynamic load applications.

The independent tests were performed in accordance with EN 1993-1-9: Design of steel structures - Part 1-9: Fatigue. A number of tests were performed at different load levels from 10,000 to 2.5 million cycles in order to determine suitable detail categories. The results from the testing were then used to calculate Safe Working Loads (including a Factor of Safety).

The new brochure explains further the steelwork clamping concept, key benefits, the free technical support services available from Lindapter, examples of typical applications, an in-depth project case study featuring Berlin Bridge and information regarding independent product approvals.

Featured in the brochure are typical applications showing connection solutions for:

- Conveyor Systems

- Cranes and Crane Rails

- Bridges & Bridge Refurbishment

- Material Handling Systems

- Hoists & Lifting Equipment

Each section includes a real-life project photograph, description of the solution and 3D and 2D drawings so the reader can quickly understand and visualise the application and relate it to their own situation.

To learn more about Lindapter solutions for Dynamic Load Applications please click here to download the brochure or email marketing@Lindapter.com to order a hard copy.

How can we

help you?

Reasons to choose Lindapter

-

Save time and money

Clamping two steel sections together avoids time-consuming welding or conventional drilling and bolting.

-

Safer connections

On-site drilling and welding is avoided, removing the need for hot work permits and encouraging safer site conditions.

-

High strength

Lindapter clamps are manufactured from high strength materials to resist high load requirements and harsh environments.

-

Industry leading approvals

Lindapter has earned a reputation synonymous with safety and reliability, gaining multiple independent approvals.

-

Adjustable

Quickly align steel sections by sliding the section into the correct position before tightening the Girder Clamp to complete the installation.

-

Free connection design

Lindapter’s experienced Engineers can design a bespoke connection based on your specific requirements free of charge.

You must have a Lindapter account to access this content

Log in to your account

Register for an account

Don't have an account?

Click here to registerAlready registered?

If you have registered for an account but have not received your confirmation email, please click here to resend.

Headquarters

Lindapter InternationalLindsay House, Brackenbeck Road

Bradford, West Yorkshire

BD7 2NF

United Kingdom Map and directions

news

- Environmental Policy

- T&Cs

- Privacy

- Cookies

- © Lindapter International 2026. All rights reserved.